20 saw blades and the grooving cutters in between are set up on the saw shaft.

20 saw blades and the grooving cutters in between are set up on the saw shaft.

One of the leading manufacturers of MDF and HDF boards in Brazil purchases a PAUL SK series panel rip saw. The company was founded in 1952 and has since developed to become a major board producer in South America, continuously further enhancing its capacities. The current production volume is 2,400,000 m³ of board material per year. In order to be able to stack and transport the high volume of raw boards, the company requires squared timber as spacers for packing purposes that allow the use of forklifts to transport and stack the materials.

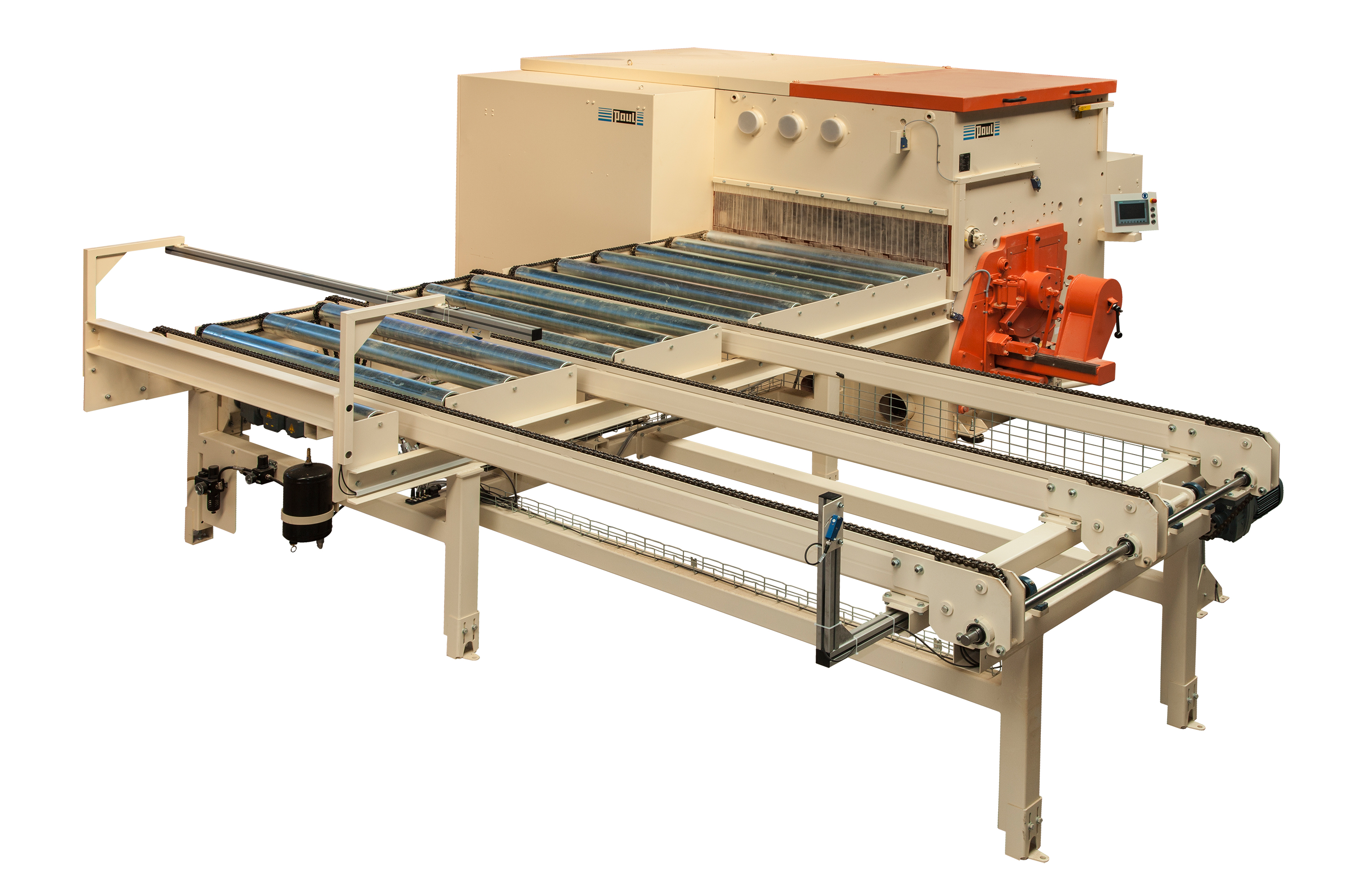

The manufacturer aims at modernizing the production of squared timber and at adapting its performance to future requirements. PAUL and another German machine manufacturer deliver the components that are required for a successful realization of this project. It is a challenging one due to the combination of the high number of tools and the thickness of the boards of up to 80 mm. With 20 saw blades, 21 grooving cutters and 2 edge hoggers on one single saw shaft, up to 21 strips with a 30 mm groove each are produced in the throughfeed at the same time. In order to provide the required resources for such high demands, the strong SK panel saw has been equipped with a high performance 260 kW engine.

The SK panel saw impressively demonstrates its capabilities, while yet not reaching its full potential. According to the manufacturer, a variety of material, such as OSB, OSL, LVL, particle, plastic, and insulating boards, can be handled without any problems. The panel saw allows for passage widths of up to 3,000 mm and material strengths of up to 150 mm. Various configurations make a broad range of further applications and processing options possible. For example, both the top and the bottom face of the boards can be processed in one single throughfeed thanks to overhead and bottom-mounted saw shafts. In addition to models featuring a continuous saw shaft, the SK Vario saw allows for a free positioning of its individually servo-driven saw blades. PLC control and touch-screen operation additionally enhance performance and convenience, while ensuring remote access for maintenance purposes.

The strong panel saw will start its long journey to South America in the second quarter, where it will be put into operation probably in the fourth quarter of 2020.