At the upcoming LIGNA (Hall 27, Booth B20), Paul Maschinenfabrik (Dürmentingen/Germany) will not only be presenting tried-and-tested technology, information and concentrated know-how, but also numerous new products and innovations for the woodworking industry. The Southern German mechanical engineering company was able to take advantage of the corona-related break in trade fairs and push ahead with interesting developments in cross-cut systems, scanner technology and automation components. The company will thus be travelling to Hanover with a modern product portfolio of both brands (Paul/Reinhardt) and is looking forward to numerous visitors and interested parties.

The highlight in scanner technology is the newly developed PAUL Rip Scanning System. The incoming workpieces are precisely measured in the longitudinal direction by means of high-resolution colour cameras and lasers. In addition to the defined wood characteristics, the optimization also takes into account crooks, re-rip pieces and the cut lengths to be produced in the further process. Customers where these systems perform their daily tasks are enthusiastic about the enormous increase in yield. The PAUL Wood Scanning System has long been known as the "best price-performance scanner on the market" for cross-cutting and sorting applications. Not yet known are the newly developed cameras with the associated software and the extension of these defect detection systems by artificial intelligence.

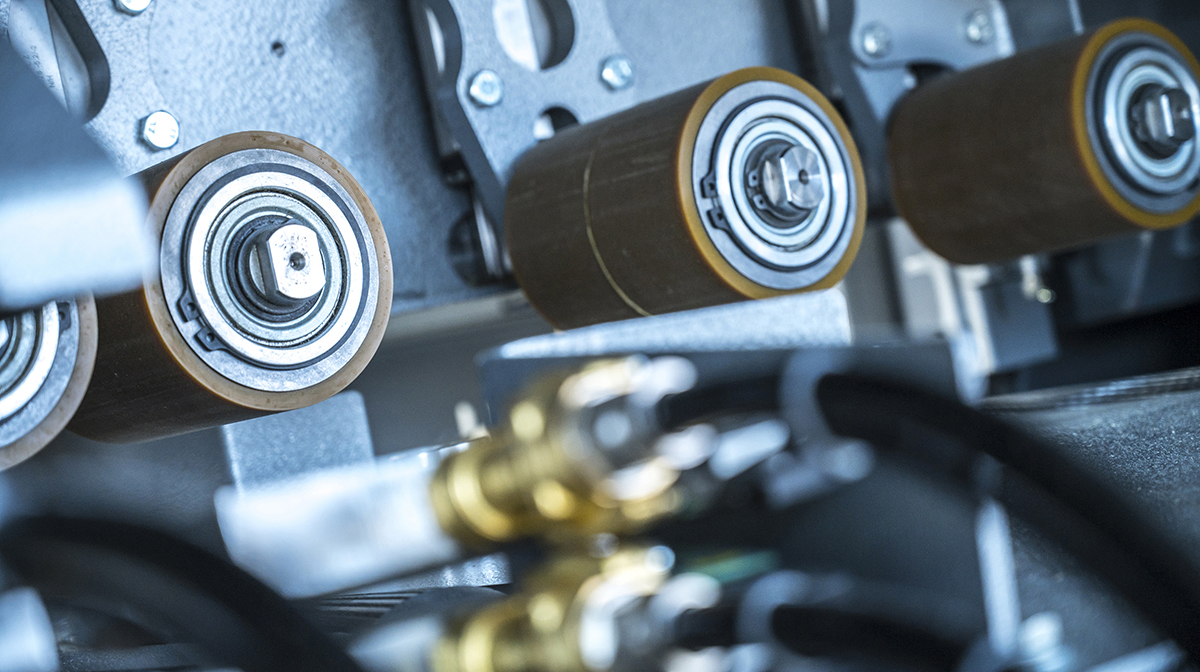

High-speed, high-precision cross-cutting is one of the outstanding features of the C11 and C14 series. Cutting times of 0.08 seconds in conjunction with new servo drives and the so-called gap-close function drive the performance data even higher. The servo-controlled kick-out system feeds the cut lengths onto the following sorting belt while the saw blade is in "descent". Thanks to the five or six generously dimensioned and hard-chrome plated feed rollers, the cutting stations have the timber fully under control. Fully automatic destacking systems and automatic stackers as well as various transport devices make every cross-cut line an economical alternative and prevent today's shortage of skilled workers.

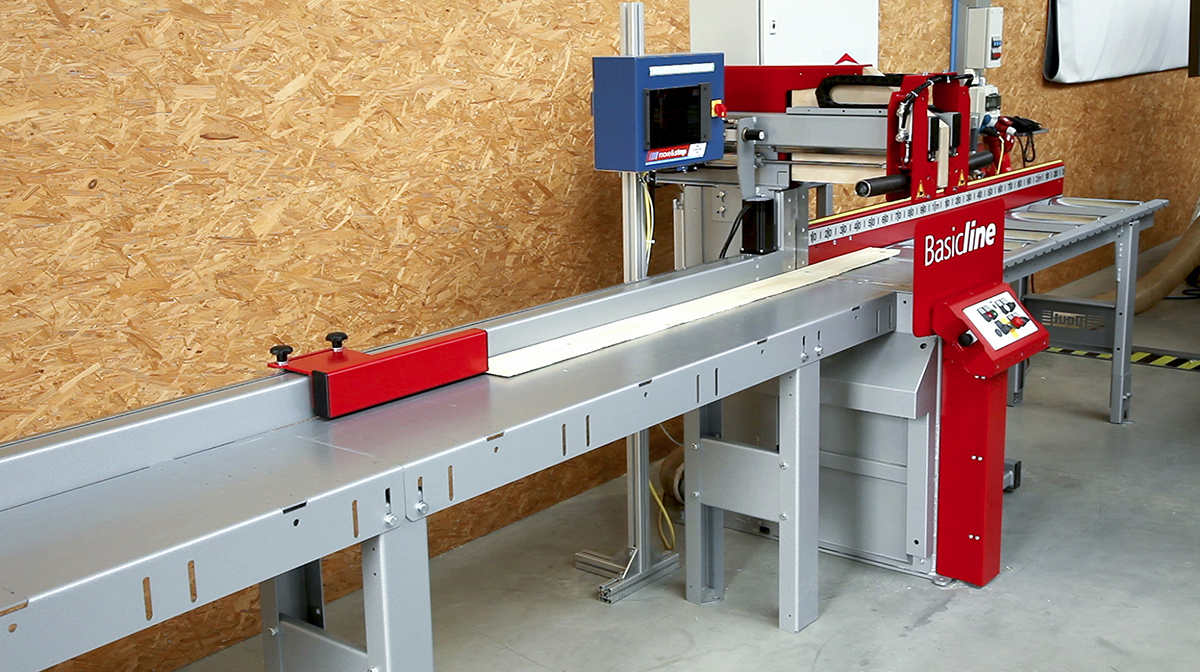

The recently revised undertable cross-cut saw type Reinhardt BasicLine with cutting heights up to 225 mm is ideal for manual length cutting. The electrically movable "Move&Stop" stop system as an extension to the manual undertable cross-cut saw offers an easy entry into the world of automation technology. Via a large touch display which can also be operated with gloves, the operator conveniently enters the desired stop position and also saves it if required. The mechanical stop then moves fully automatically to the desired position, which relieves the worker and saves a considerable amount of time. The system can be used either as a mechanical stop or as a pusher and can be combined not only with Paul/Reinhardt machines, but also with machines from other manufacturers.

The Reinhardt SlimLine series has also been completely revised both visually and technically. The positioning pusher can now always be lifted/lowered vertically by means of a linear guide as standard. The swivel unit, which enables a convenient saw blade change, is particularly pleasing for the user. In combination with the ProLock quick-changing system, tool change cannot be solved any better. Since work on a cross-cut system is hard and involves physical exertion, Paul developed both semi-automatic and fully automatic automation and stacking systems that enable efficient use of the circular saw. With the clever and flexible "Stack&Move" system, the ejector of the circular saw transports the finished workpieces directly onto the pallet of an electric stacker, thus eliminating the need for stacking with muscle power.

The Paul team will be available at LIGNA to advise all interested parties on its entire product range, extend a warm welcome and looks forward to welcoming visitors.