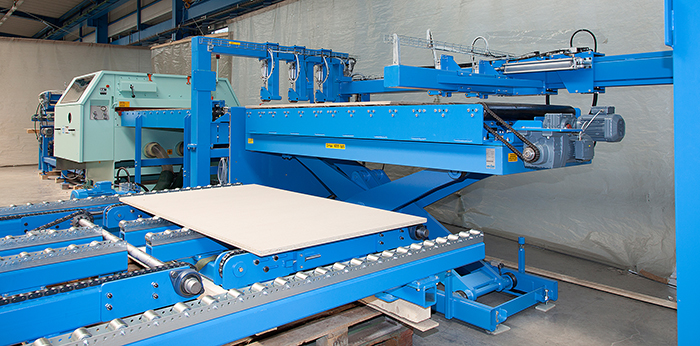

Fully automatic panel feeding system with panel stack buffer station, lift table and pusher

Fully automatic panel feeding system with panel stack buffer station, lift table and pusher

At times of rising wages automation is becoming an ever more important aspect in order to remain competitive in the long run. Also the customers of PAUL Maschinenfabrik are only too aware of this. As a worldwide renowned specialist for throughfeed panel rip saws, PAUL produces multirip saws in opening widths ranging from 800 to 3000 mm with a focus on meeting specific customer requirements. These machines are available with a fixed saw configuration or servo-controlled moving saws, making them also suitable for ‘batch size one’ production. They are used for processing a variety of materials, from conventional particle or MDF panels via coated panels with sensitive surfaces through to plastic or composite materials.

To increase the efficiency in panel ripping, fully automatic loading and unloading systems play a key role. Here again, PAUL has made a name for itself on several recent occasions. There is almost no limit to the panel format to be handled. The latest system is designed to destack panels of a max. length of 11 m and a max. width of 2.5 m, i.e. with an area of 27.5 sq.m. corresponding to that of an average living room. The pusher-type feeding unit aligns these giants and feeds them into a K34GX/2600 multirip saw. On this system the panels arrive in stacks which are moved to the right height by a lifting device. Depending on the application concerned PAUL also offers alternative solutions, e.g. using a vacuum destacker or articulated robots. Taking into account the space available at site, the design engineers determine the system generating maximum customer value. Other functions, such as feeding the machine with two panels side by side or the automatic return and disposal of stack cover sheets and empty pallets are also offered by PAUL. In the laminate flooring production camera alignment systems are used. Image recognition software ensures that the panels are correctly aligned in accordance with the surface pattern. PAUL offers a great variety of fully automatic feeding systems, to mention all of them would go beyond the scope of this report. On request, the PAUL team will be pleased to compile customer-oriented and customized solutions.

Automation is also gaining increasing importance on the outfeed side of the multirip saw. The ripped strips can be fed by any conceivable system to any downstream processing step or be stacked by ejection or vacuum systems, even without gaps between the strips. Paul also supplies special panel cleaning and turning devices, etc. State-of-the-art control technology is used for controlling the infeed system, rip saw and other system components. All system components are designed for remote maintenance.

Panel handling systems allow a significant increase in machine performance, process reliability and accuracy as well as an almost fully automatic operation with reduced or even without any extra manpower.