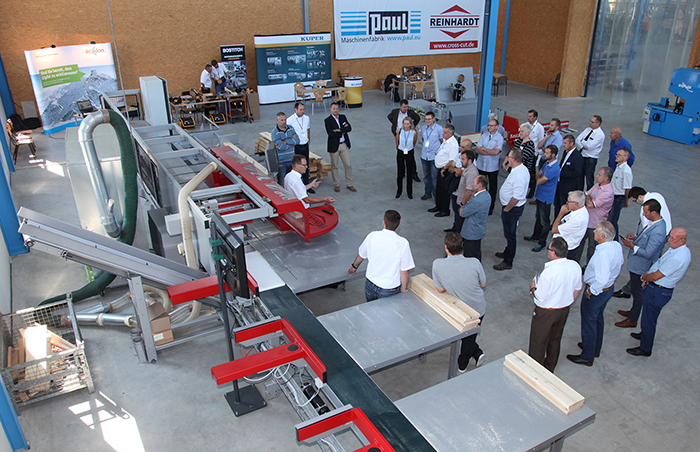

The machine demonstrations (here the Reinhardt SlimeLine F) attracted great interest

The machine demonstrations (here the Reinhardt SlimeLine F) attracted great interest

On 8th and 9th September PAUL Maschinenfabrik presented its two brands, PAUL and Reinhardt, for the first time at its in-house ‘Expo’. The event with its highlights for the packaging industry and for ripping and cross-cutting hardwoods generated great interest, attracting approx. 160 visitors from 20 nations. Also the guest exhibitors were entirely satisfied with the feedback. They complemented the exhibitor’s presentations with interesting exhibits of the entire woodworking industry process chain. Apart from the PAUL and Reinhardt machine demonstrations, visitors had an opportunity to see, inter alia, a horizontal bandsaw, an industrial robot or a band resaw. Not only the participating companies Acadon (trade software), Bostitch (tooling), Kuper (woodworking machinery), Bidac (automation solutions), SMB (finger jointers), Stenner (band resaws), Kuka (industrial robots), Schmalz (vacuum technology), Limab (laser systems), WoodEye (wood scanners), Sicko (feeding/stacking systems) and Serra (sawmilling technology) reported on interesting discussions during the exhibition and the convivial get-together in the beer garden, PAUL also initiated a number of projects at the Expo.

A major focus of the demonstrations was the SlimLine F of the Reinhardt brand as well as the PAUL hardwood ripping and cross-cutting system. The SlimLine F that has been specifically developed for the packaging industry is a combination of a push-feed cross-cut saw and a rip saw. It is ideally suitable for the automated cutting of closed-deck pallets or top, bottom and wall elements of cases on a single machine. Developed in 2013, this machine type has been sold to a number of customers already and has been further developed and improved based on the experience gained. Orders are entered via the CNC control on the touch screen or alternatively via the trade software from Acadon. Ejectors on the outfeed side sort the cut pieces based on customer orders. To keep an overview, a sorting monitor and ink-jet printer are provided. Tools for the further processing into cases and pallets were demonstrated by Bostitch.

The PAUL hardwood ripping and cross-cutting system shown is going to be delivered to a customer in Croatia who specializes in the production of sawn Oak timber. It comprises an automatic AB-MA infeed system of the Power_Rip family and a KME3 edger/multirip saw which allows the operator to either assess and grade the incoming boards himself or leave this task to the infeed system. The ripped workpieces are cut to length on a C14_MKL optimizing cross-cut and length sorting system. In addition, the customer is supplied with a tilt hoist destacker of the Reinhardt brand for feeding an existing board edger.

In July this year PAUL Maschinenfabrik acquired a majority interest in SMB Maschinenbau GmbH. This strategic merger will further strengthen the already strong position of the two companies. With this milestone in the history of SMB and PAUL they are gearing up to meet customer requirements in the years ahead. After all, the trend towards single-source suppliers of complete production lines is unmistakable. The SMB product range with its high-efficiency finger jointers, gluing machinery, rosser-head debarkers and butt-end reducers provides an ideal complement to the PAUL range. This will give visitors of the next PAUL Expo a chance to experience these machines as well making the event even more interesting.