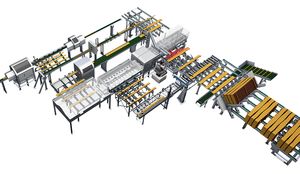

We supply machines for ripping all kinds of panels. As the fields of application are both varied and highly individual, we offer a suitable solution to cover every kind of assignment. Our supply range encompasses not only stand-alone machines but also project-processed complete solutions offering a high degree of automation.

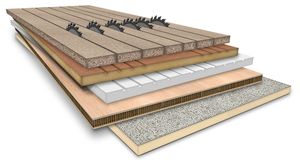

These machines are used in all fields of industry: in sawmills and in the furniture industry, for the production of parquetry and laminated flooring, pallets, concrete moulds, kitchen front panels, glued up panels, cement-bonded particle boards, profile strips, door skins, in packaging, window, bed and coffin factories, in the plastics, WPC, OSB, OSL, LVL panel or cardboard industry and in many other applications areas.

Our ripsaws for solid wood are suitable for use in both hardwood and softwood sawmills following a frame saw or band saw. Naturally, we also offer machines for secondary wood processing applications. Whether manually or fully automatically loaded, whether for hardwood or softwood, PAUL offers the right equipment for every application: Large heavy-duty circular sawing machinery for resawing as well as solid edging and multi-ripping saws for the manual edging of boards and planks and producing battens.

Our experience in the field of CNC cross-cut systems stems back to 1976 – longer than any other company! At that time, PAUL was the first German company to construct a CNC-controlled cross-cut saw capable of optimization. This machine type was continuously further developed and improved over decades. Using a variety of optimization algorithms and based on a superb standard of mechanical engineering excellence, we are able to offer customers minimal cutting waste, i.e. maximum yield from the starting materials used. By maximizing profits in this way, the payback period for investment in a PAUL optimizing cross-cut saw is slashed to a minimum. By maximizing profits in this way, the payback period for investment in a PAUL optimizing cross-cut saw is slashed to a minimum.

We develop custom-tailored machine concepts for every application offering our customers an efficient one-stop back-up service, from project planning through to installation support. PAUL cross-cut systems are in operation all over the world, e.g. in sawmills, finger-jointing lines, in the glulam industry, in the furniture, window, plastics, flooring industries, in the production of packaging cases and pallets and in many other fields.

Automated complete solutions are implemented through interlinking of automated handling equipment, cross-cut systems and ripsaws. Components from other manufacturers are integrated, where necessary. Higher feed rates, interlinked processing steps, accurate workpiece guidance and automatic work flows lead to a significant improvement in productivity. Operator workload is reduced and the standard of security increased.